01270 753323

Our services

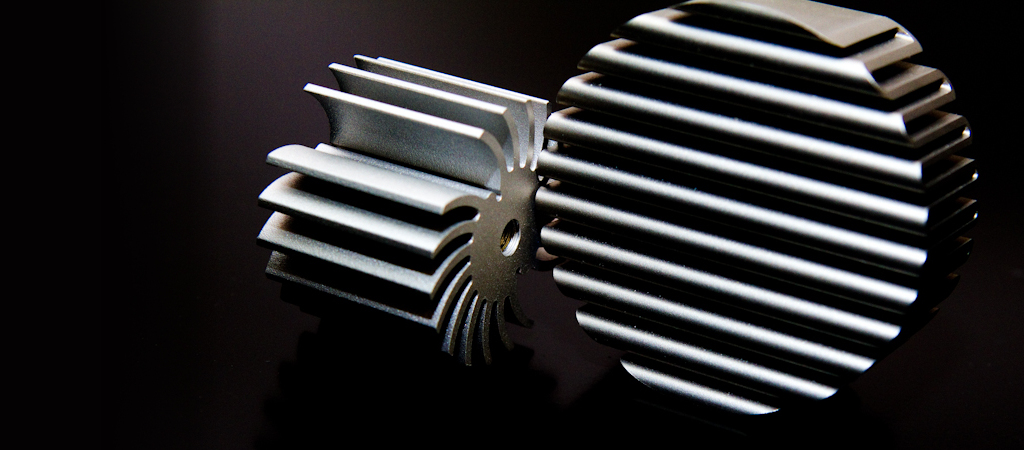

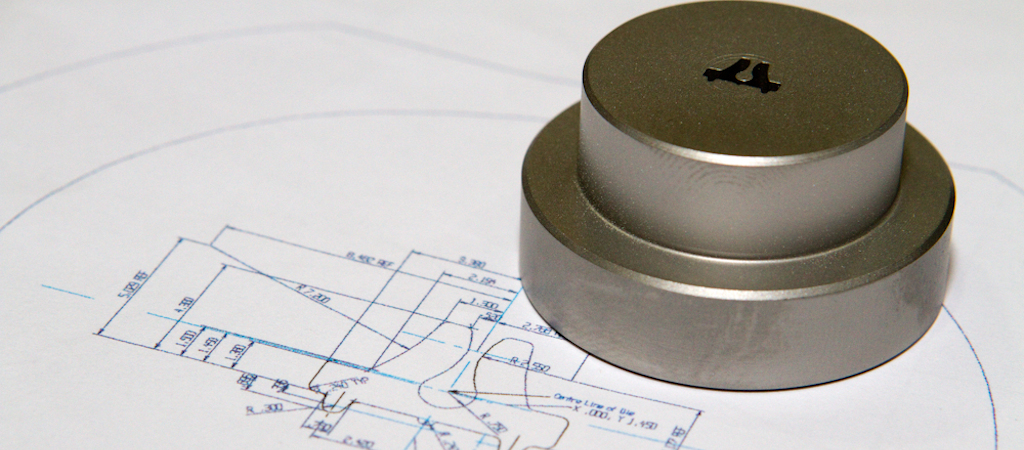

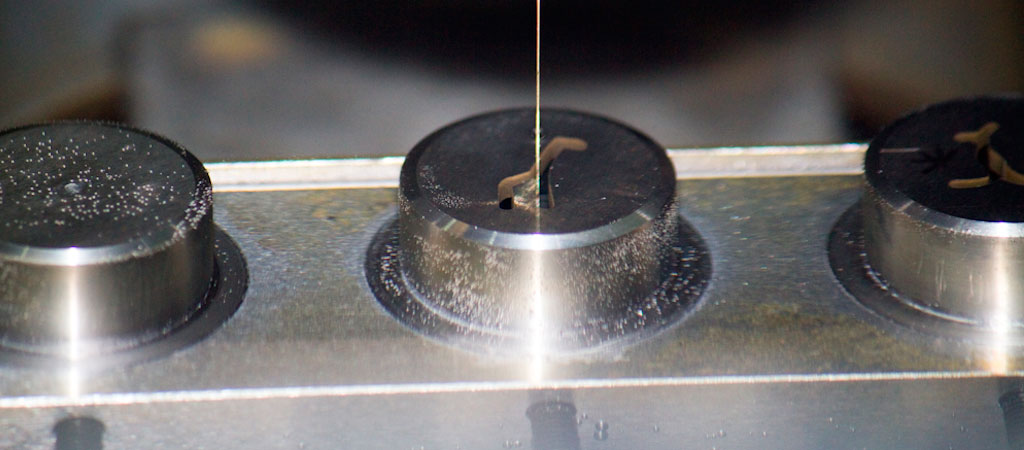

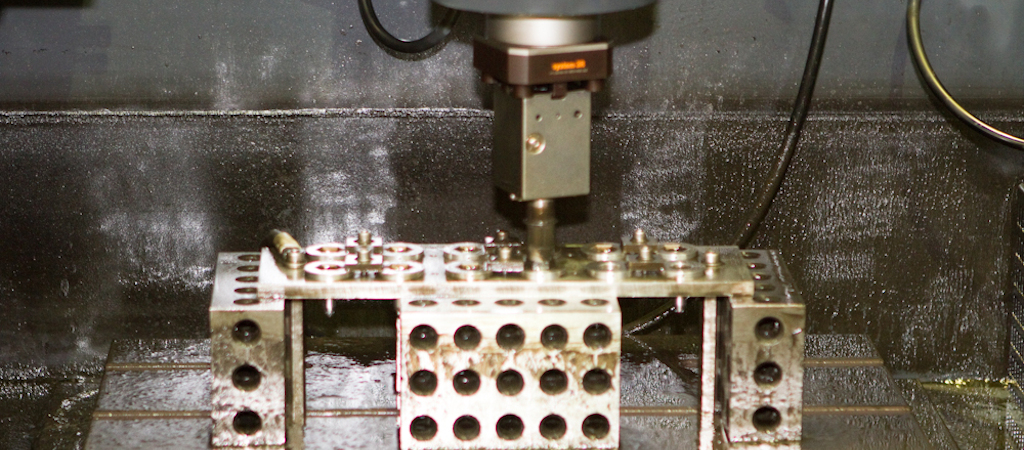

EDM is a machining method of removing material by discharge heat, by which its surface is melted and vaporised and is used in an extensive variety of different industries and is a beneficial machining option for today’s engineer. Wire-Cut EDM, Die-Sinker EDM and Small Hole Drilling EDM are extremely precise time saving and cost effective methods of cutting, shaping and re-sizing of hard or soft, electrically conductive materials.

Whether the components are manufactured from non-exotic materials such as Copper, Steel, Aluminium, Brass or Tungsten Carbide or more exotic, less easy to conventionally machine materials, such as Titanium, Inconel, Nimonics, Graphite, Duplex, Silver and Gold etc, we can cater for all. What also makes EDM different to other machining methods is that it is a non-contact process that induces no stresses into the work place. Accuracy and repeatability is an in-built characteristic of these methods of machining, using the Sodick machinery we have at Cheshire Wire Erosion. Using the Sodick machinery is evidence of the fact that we are investing in producing quality.

Concluding with a quality product, supplies on-time and at a good price. Underpinned by our BS-EN-ISO 9001 accreditation.

Services

- Wire-Cut EDM

- Die-Sinker EDM

- Small Hole Drilling EDM

Areas of Industry

- Aerospace

- Automotive

- Ceramics

- Electronics

- Food Production

- General Engineering

- Hobbyist

- Horology

- Jewellery

- Medical

- Motorsport

- Power Generation

- Petro Chemical

- Pharmaceutical

- Precision Engineers

- Railway/Locomotive Engineering

- Ship Building

- Universities and Colleges

Types of Work

- Precision Components

- Prototypes

- Small and Large Batch Work

- Exotic material Machining

- Extrusion Tooling

- Copper

- Aluminium

- Plastic etc.

- Press Tooling

- Mould tooling

- Plastic

- Rubber

- Selective Laser Melting Parts Removal